Recovery of defects

In July 2024, the Spartan was presented to the technical inspection.

The report was catastrophic as explained on the "Bodywork and Remontage" page of this site.

A team of mechanics had been formed and mobilised for more than a week to take over the defects of the Boutier Retro Motors garage and allow the car to be presented again to the technical

inspection.

If indeed the second technical inspection was virgin of any defect, in use, many other problems have appeared and required major work, here are the details.

Electricity

Big problems have already been explained on the "Bodywork and Remantage" page of this site.

Other malfunctions were updated during the August 2024 road trip in England.

An electrical failure had immobilised the vehicle in the Bristol area.

A poorly connected power wire had come off on the hazard light circuit and caused a short circuit.

Two English garages had been asked to put the car back into working order, and neither of them had managed to do it completely.

Only a makeshift repair had allowed the car to start again, without everything being operational.

For these two garages the observation was the same : the electrical circuit was too poorly made to be repairable.

The wiring had been done in anarchic way with wires forming real bags of knots.

No terminal block had been installed and the power bypasses made were out of standard.

This was incomprehensible, even for a car electrician.

Indeed, some wires had too long lengths, others had been extended without any respect for colours, as here where the wires change colour 3 times over 60 cm :

Faced with the poor quality of this work, only one solution is necessary: dismantle everything to redo everything correctly.

The key contactor damaged by the short circuit in England needs to be replaced.

Extended wires that change colour must also be changed.

Three terminal blocks will be set up to properly distribute the power supply of the different organs, and to connect the masses correctly.

A compartment will be created to install them cleanly and receive the electrical relays.

In addition, as the commodo had been plugged in, the fact of going into full headlight did not cut the codes.

Thus, the two filaments of the H4 bulbs operated simultaneously, which had caused the bulbs to overheat to the point of melting their electrical plugs.

The connections of Boutier Rétro Motors were really dangerous.

The headlight sheets obviously had to be changed as well.

The car radio

Since it is necessary to demonstrate the car radio to redo the electricity, this will be an opportunity to fix it correctly.

It had been installed on a simple sheet metal attached to the dashboard revealing the electrical wires on each side which was unsightly.

A real console will be set up.

The brakes

The brake hoses that Boutier Rétro Motors had put on the Spartan had been refused during the technical inspection.

All too short, they almost reached the breaking point at the front when we turned the steering wheel all the way up, and if we lifted the car it was the rear brake hose that limited the stroke of

the bridge that was hanging from this hose.

I still can't understand how a professional could do this.

I come back here to the subject to mount the hoses that came to replace the old dangerous assembly.

From the first hundreds of kilometres travelled, the incessant noise made by the brake pads that constantly vibrated and tapped on the calipers became unbearable.

The first professional interviewed to solve this problem immediately realised that the brakes had been wrongly mounted.

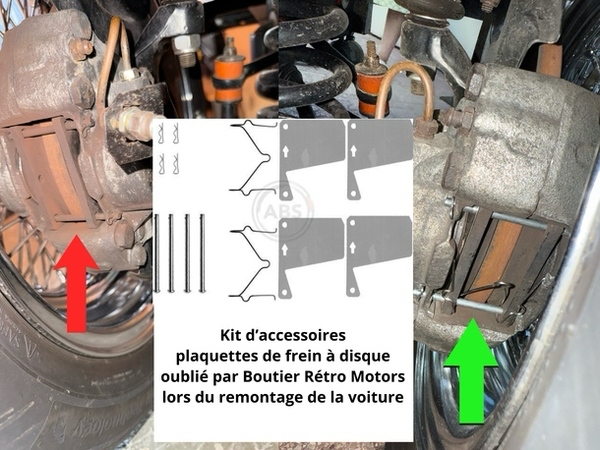

The Boutier Rétro Motors garage had forgotten part of the braking system when it reassembled the car's brakes.

Incredible !

The accessory kit of the disc brake pads had not been put :

The exhaust

The garage had told me that it had painted black the part of the stainless steel tubes located in the engine compartment to make it more aesthetic in the engine.

At no time would I have imagined that it was to mask that one of the two tubes had been put in steel !!!

Even more annoying, the line is poorly made and greatly harms the performance of the engine.

The line was designed in defiance of mechanical rules, the pressures are unbalanced between the outputs of cylinders 1 and 3 and cylinders 2 and 4 which were directed independently towards their

respective lateral exits.

Only one solution is needed, to redo the job properly!

The line is redone, by a serious professional, according to the rules of the art...

An X-pipe is set up to balance the pressures of each of the side outlets, and stainless steel exhaust hoses now make it possible to absorb engine movements.

The trunck

Two problems were annoying in the trunk :

- The screw heads that fix the rear wings were protruding inside the trunk and damaged what we came to put in it.

They have been replaced by adapted stainless steel screws with a flat head.

- With the spare wheel on the trunk, it was a real strength test to open it. It took 2 to access it: one to hold it, and one to store or unload its contents.

Cylinders have been placed on the locations provided for this purpose.

The spare wheel support

The Boutier Rétro Motors garage had used 2 steel tubes covered with a piece of stainless steel sheet metal to manufacture the spare wheel support.

Two problems required the support to be redone correctly :

- The steel tubes quickly rusted, and when the car took the rain, traces of rust flowed to the bottom of the trunk.

- The stainless steel sheets that covered these tubes were very thin and formed real razors on their edges.

Every time I cleaned the car, I cut my fingers.

Two supports have been redone correctly, in aluminum, with plugs at their ends :

The power steering

During the reassembly of the engine, the Boutier Rétro Motors garage had connected the power steering pump to its tank using two pieces of hoses, identical, new, connected to each other.

Why did you make such a montage, when a simple hose would have been perfectly convenient ?

This assembly did not hold, a leak occurred at the connection between the two pieces of hose...

Obviously, there is no question of repairing the leak at the level of what was already similar to patching, a silicone hose came to replace this risky assembly.

We leave the recovery of the defects, although others, not detailed here, had to be corrected, to move on to a more encouraging subject.

Indeed, having paid the full price for the work described above on this page (and on the "Bodywork and Reassembly" and "Unique Parts" pages) to have them redone, as soon as they are completed, by

another serious professional, is a prejudice that is difficult to digest.

After dealing with the problems, it was finally time to move on to the improvements to be made, they should have been the starting point of the winter work.

A new audio system has been integrated into The French Spartan to enhance the rides.

Small lights took place very discreetly under the front bumper of the Spartan. Probably frightened by the electrical breakdowns suffered during the last road trip in England that had made us lose

the use of the headlights, I wanted additional lighting so as not to relive such a difficulty.

In addition, they will prove very useful on the small winding roads of remote places where the Spartan is promised beautiful trips.

Finally, wind screens have come to improve interior comfort for long convertible journeys.

Windscreens

To make custom wind screens, many models have been modelled to find the design that would best suit the Spartan.

Here, one of the models that will be further modified before being selected :

The chrome hinges were found at a Morgan specialist in England, and the windows were cut and engraved in France.

It took considerable work to renovate this Spartan, and months of additional work to redo almost all the reassembly operations done by a professional.

In addition to a waste of time, the recovery of defects also represents a considerable cost.

This task on the board should not mask the work of all the other professionals who contributed to the renovation of The French Spartan.

I had the chance to meet real enthusiasts who did a remarkable job, and, in the end, only the result counts :